Syfar cork products

Syfar promotes low environmental impact technologies , offering high quality products and extreme performance . Our continuous research offers innovative solutions for insulation and comfort in green building.

since 1996

Syfar is dedicated to the production and processing of cork

The current governance derives from the experience of a family business, present in the Nebrodi woods since the 1970s.

Tradition, innovation and sustainability

Our vision is to be the leader in the use of cork in green building, offering highly innovative products of high quality standards, which meet the needs of thermal and acoustic insulation, guaranteeing environmental comfort and environmental sustainability for future generations.

1. Starting profile

The base on which the insulation is applied: an aluminum or PVC perimeter profile fixed to the walls.

2. Glue

Composed of hydraulic lime, it fixes the panel to the wall for perfect and long-lasting adhesion.

3. Insulating material

Cork panel adhering to the wall, of different thicknesses, fixed by means of the glue, a component of the cork coat.

4. Dowels

Inserted into the panel, they are anchored to the wall with the aid of the adhesive, for stable and long-lasting adhesion.

5. Smoothing

Even out the surface of the cork boards to apply the reinforcing mesh.

6. Rebar mesh

Fiberglass mesh to reinforce the plaster and prevent cracks, applied to the surface of the skim coat.

7. Primer

Silicate-based insulating varnish, increases the resistance and adhesion of the reinforcing mesh.

8. Siloxane finish

Protects the cork coat from the wear and tear of time thanks to its resistance to bad weather.

8 layers for effective insulation

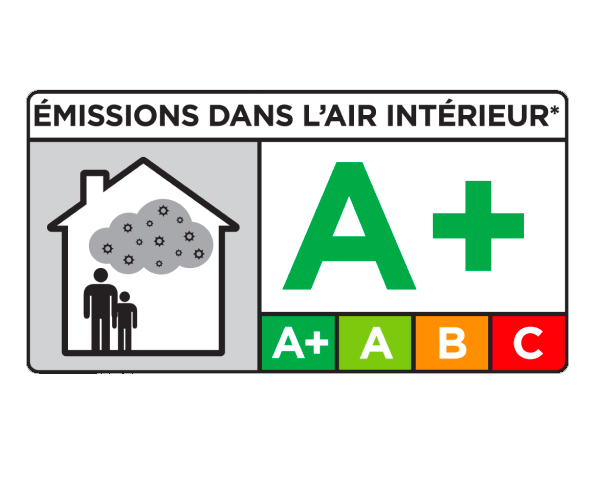

Cork is a natural material with excellent insulating, acoustic and thermal properties, water repellent, fire and mold resistant. Its use in green building ensures maximum living comfort, safeguarding the environment and people's health, thanks to its sustainable production and reduced environmental impact.

Building according to nature

The transformation of the raw material