Syfar is based in Contrada Furiano, in Acquedolci, Sicily.

It is a limited liability capital company, established by four brothers who have chosen to expand the family business of raw cork production into a modern enterprise, specialized in the collection and transformation of natural and organic products of noble plants, including the Quercus suber. The Scaffidi Abate brothers, currently at the helm of the company, have built a modern factory in which the traditional cork collection activities are combined with the production of semi-finished products for green building, such as panels and granulates. Thanks to the high quality of the raw material and the large production, it was possible to create an avant-garde processing plant, respectful of the environment and innovative for the type of cork transformation.

Syfar is based in Contrada Furiano, in Acquedolci, Sicily.

It is a limited liability capital company, established by four brothers who have chosen to expand the family business of raw cork production into a modern enterprise, specialized in the collection and transformation of natural and organic products of noble plants, including the Quercus suber. The Scaffidi Abate brothers, currently at the helm of the company, have built a modern factory in which the traditional cork collection activities are combined with the production of semi-finished products for green building, such as panels and granulates. Thanks to the high quality of the raw material and the large production, it was possible to create an avant-garde processing plant, respectful of the environment and innovative for the type of cork transformation.

Lo stabile è ubicato nella zona industriale di Tempio Pausania (SS), ovvero in Gallura, terra caratterizzata da una tradizione sughericola longeva e dunque dedita alla lavorazione di questa eccellenza del territorio.Lo stabile vanta una superficie utile di oltre 5000mq con un'area cortilizia dedicata allo stivaggio ed alla stagionatura del sughero.

La Sardegna è una delle principali aree produttrici di sughero a livello mondiale. La sua quercia da sughero (Quercus suber) cresce spontanea nei boschi dell’isola, grazie al clima mite e alla biodiversità mediterranea. La raccolta avviene ciclicamente, senza abbattere l’albero, rispettando tradizioni secolari tramandate di generazione in generazione. Il sughero sardo è apprezzato per la qualità, l’elasticità e la purezza della corteccia, che lo rendono ideale per la produzione di tappi, pannelli isolanti e manufatti destinati alla bioedilizia e al design.

Lo stabile è ubicato nella zona industriale di Tempio Pausania (SS), ovvero in Gallura, terra caratterizzata da una tradizione sughericola longeva e dunque dedita alla lavorazione di questa eccellenza del territorio.Lo stabile vanta una superficie utile di oltre 5000mq con un'area cortilizia dedicata allo stivaggio ed alla stagionatura del sughero.

La Sardegna è una delle principali aree produttrici di sughero a livello mondiale. La sua quercia da sughero (Quercus suber) cresce spontanea nei boschi dell’isola, grazie al clima mite e alla biodiversità mediterranea. La raccolta avviene ciclicamente, senza abbattere l’albero, rispettando tradizioni secolari tramandate di generazione in generazione. Il sughero sardo è apprezzato per la qualità, l’elasticità e la purezza della corteccia, che lo rendono ideale per la produzione di tappi, pannelli isolanti e manufatti destinati alla bioedilizia e al design.

Syfar Promotes

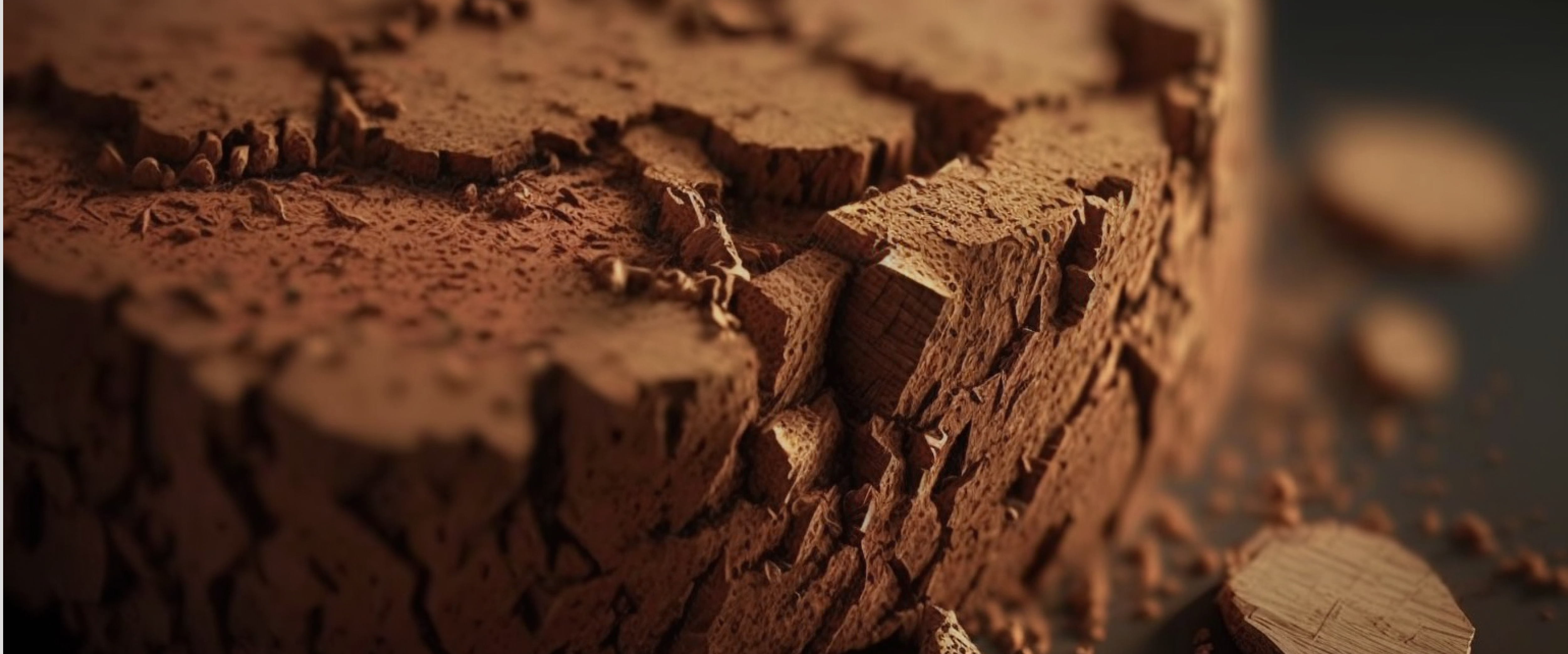

Cork is a valuable and exclusively Mediterranean natural product made from the outer bark of the cork oak. It is a renewable and eco-sustainable raw material: it regenerates over the years , after being manually removed from the trunk during the summer, and without any tree felling. The first peeling of a young oak occurs when the plant has reached twenty-five years of age and subsequent extractions take place at regular intervals of at least nine years. Cork forests are one of the richest ecosystems in the world, they preserve biodiversity and protect the environment from fires and desertification. Our "closed cycle" production begins in the Sicilian cork oak forests with manual extraction and peeling operations, and after at least six months of seasoning the cork planks are selected and subjected to boiling, crushing, grinding in depression and agglomeration. The panels thus produced are characterized by their density, size and very high quality performance : SYFAR products are in fact extremely elastic and particularly insulating and breathable.

Cork is a valuable and exclusively Mediterranean natural product made from the outer bark of the cork oak. It is a renewable and eco-sustainable raw material: it regenerates over the years , after being manually removed from the trunk during the summer, and without any tree felling. The first peeling of a young oak occurs when the plant has reached twenty-five years of age and subsequent extractions take place at regular intervals of at least nine years. Cork forests are one of the richest ecosystems in the world, they preserve biodiversity and protect the environment from fires and desertification. Our "closed cycle" production begins in the Sicilian cork oak forests with manual extraction and peeling operations, and after at least six months of seasoning the cork planks are selected and subjected to boiling, crushing, grinding in depression and agglomeration. The panels thus produced are characterized by their density, size and very high quality performance : SYFAR products are in fact extremely elastic and particularly insulating and breathable.

Decortication is the process of removing the bark from the trunk of the Quercus suber, the tree from which cork is obtained. The bark is removed every 9-12 years , in an operation called "whitening". After removal, the bark is left to dry in the open air for a few months before being transported to the processing plant. The peeling carried out by Syfar takes place only in the summer months, from 15 May to 31 August. This period is dictated by forest legislation, which sets May 15 as the date on which it is possible to start the process. All the activity that is carried out in the woods (cutting, cleaning, decotic...) requires a specific authorization from the Departmental Inspectorate of Forests and any other Bodies (e.g. Park). In addition, special climatic conditions of temperature and humidity are required. In the absence of these conditions, the bark does not peel off. Therefore, Syfar employs more than 100 scorzini, between direct and related employees, to carry out this seasonal activity.

Decortication is the process of removing the bark from the trunk of the Quercus suber, the tree from which cork is obtained. The bark is removed every 9-12 years , in an operation called "whitening". After removal, the bark is left to dry in the open air for a few months before being transported to the processing plant. The peeling carried out by Syfar takes place only in the summer months, from 15 May to 31 August. This period is dictated by forest legislation, which sets May 15 as the date on which it is possible to start the process. All the activity that is carried out in the woods (cutting, cleaning, decotic...) requires a specific authorization from the Departmental Inspectorate of Forests and any other Bodies (e.g. Park). In addition, special climatic conditions of temperature and humidity are required. In the absence of these conditions, the bark does not peel off. Therefore, Syfar employs more than 100 scorzini, between direct and related employees, to carry out this seasonal activity.

Contact us